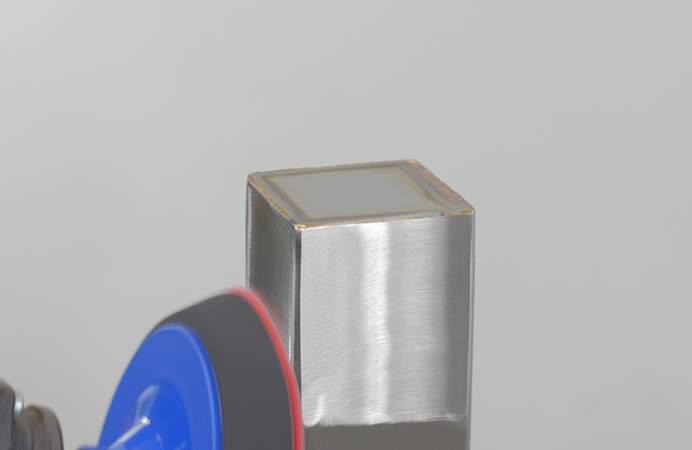

weld seam grinding and polishing railpole lid

Materials

Use the Inox angle grinder, the adhesive backing pad hard and the ceramic Velcro pad grain 120 to remove the weld.

Note:

Guide the machine horizontally in the direction of the arrow.

Recommended speed: ca 3.000 rpm

Remove the grinding marks with the medium backing pad and the Trizact velcro disc A100 (220 grit).

Note:

Guide the machine vertically in the direction of the arrow.

Recommended speed: ca 2.100 rpm

Reduce the surface roughness with the medium backing pad and the Trizact velcro disc A45 (grit 400).

Note:

Guide the machine horizontally in the direction of the arrow.

Recommended speed: ca 2.100 rpm

Using the medium backing and the Trizact velcro disc, A45 (grit 400), pre-grind the edges

Note:

Guide the machine horizontally in the direction of the arrow.

Recommended speed: ca 2.100 rpm

Use hard backing pad and Trizact velcro disc, A16 (1200 grit) to remove tarnish from the lid surface.

Note:

Recommended speed: ca 2.100 rpm

Firmly harden the edges with the backing pad and the Trizact velcro disc, A16 (grit 1200).

Note:

Guide the machine horizontally in the direction of the arrow.

Recommended speed: ca 2.100 rpm

Pick up the high gloss polishing paste with the cloth polishing roller.

Polish the lid surface with the cloth polishing roller and the high gloss polishing paste.

Note:

If there are polishing residues, they should be removed with the microfibre cloth.

Recommended speed: ca. 2,100 rpm

Use the folded non-woven ring orange to align the grinding pattern on the post sides.

Note:

Guide the machine vertically in the direction of the arrow.

Recommended speed: ca. 2,100 rpm

Pole with polished finish and polished lid.

Obere Hommeswiese 41-45

57258 Freudenberg

Germany

Fax : +49 2734-28474-10

E-Mail: info@gebrax.de