mitre grinding 90°

Materials

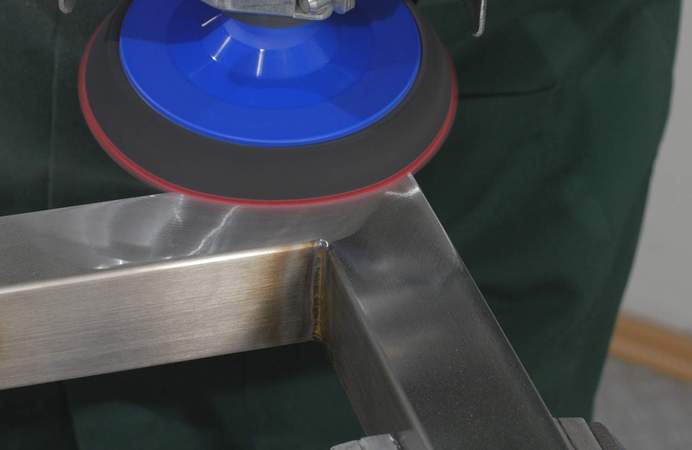

Use the Inox angle grinder, the back up pad hard and the velcro ceramic disc grit 120 to remove the weld.

Note:

Guide the machine in the direction of the arrow.

The angle grinder should have an angle of 10-15 ° to the workpiece in order to increase the removal rate and service life of the grinding tool.

Recommended speed: approx. 3,000 rpm

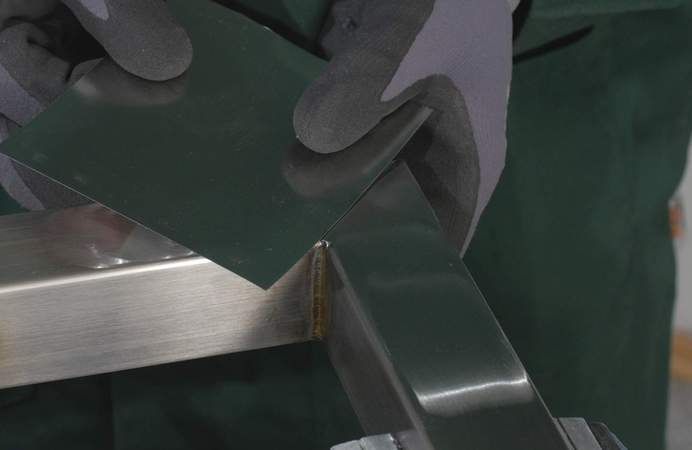

Use the medium back up pad and the Trizact velcro disc A100 (grit 220) to remove the grinding marks.

Note:

Guide the machine in the direction of the arrow.

The angle grinder should have an angle of 10-15 ° to the workpiece in order to increase the removal rate and service life of the grinding tool.

Recommended speed: ca. 2,100 rpm

Use the medium back up pad and the Trizact velcro disc A45 (grit 400) to reduce the roughness.

Note:

Guide the machine in the direction of the arrow.

The angle grinder should have an angle of 10-15 ° to the workpiece in order to increase the removal rate and service life of the grinding tool.

Due to the changed grinding direction first approaches of the miter seam are generated. At the same time, bumps and scratches are eliminated. For the subsequent finish grinding, it is advantageous not to grind beyond the miter. In order to avoid adhesive residue, it is advisable to let the material cool down.

Recommended speed: about 2,100 rpm

Mask the miter exactly with the self-adhesive stainless steel tape.

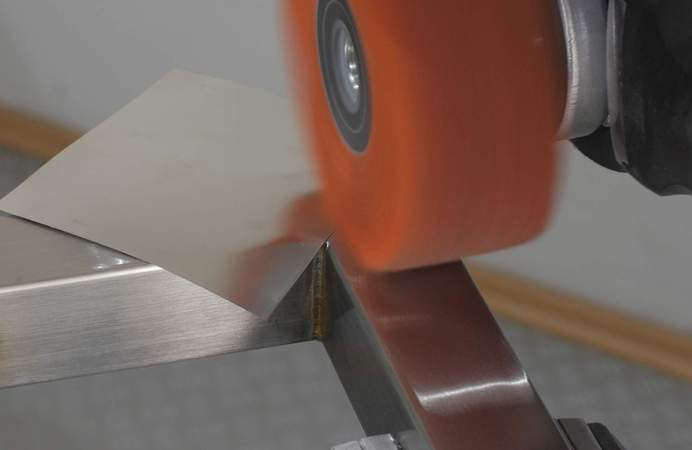

Mount the satin finishing attachment MB 650 SV on the angle grinder.

Adjust the grinding pattern with the orange folding ring.

Note:

Beginning the work on the weld with a left-to-right movement has the advantages to detect any existing grinding marks of the Trizact A45 and to eliminate it at the same time.

Finish grinding is achieved with fast, even movements of the machine in the direction of the arrow.

Recommended speed: ca. 2,100 rpm

Peel off the stainless steel tape and after a short cooling stick it onto the just grinded surface.

Grind also the other side with the folding ring orange to match the grinding pattern.

Note:

Beginning the work on the weld with a left-to-right movement has the advantages to detect any existing grinding marks of the Trizact A45 and to eliminate it at the same time.

Finish grinding is achieved with fast, even movements of the machine in the direction of the arrow. Recommended speed: ca. 2,100 rpm

The stainless steel adhesive tape can be used several times if the peel-off film is applied to the adhesive surface after application.

Adhesive residues can be wiped off with the cleaner and the microfibre cloth.

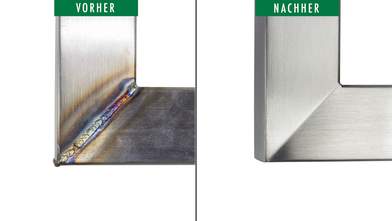

Surface with a great miter.

Obere Hommeswiese 41-45

57258 Freudenberg

Germany

Fax : +49 2734-28474-10

E-Mail: info@gebrax.de